Vans and step vans that represent about half the commercial vehicles on North American roads could be fully electrified using today’s technology, the North American Council for Freight Efficiency (NACFE) has concluded.

And electrifying all such vehicles in the U.S. and Canada would annually save nearly 18.9 billion liters of gasoline and 43.5 million tons of carbon dioxide emissions, the council added in its Electric Trucks Have Arrived report.

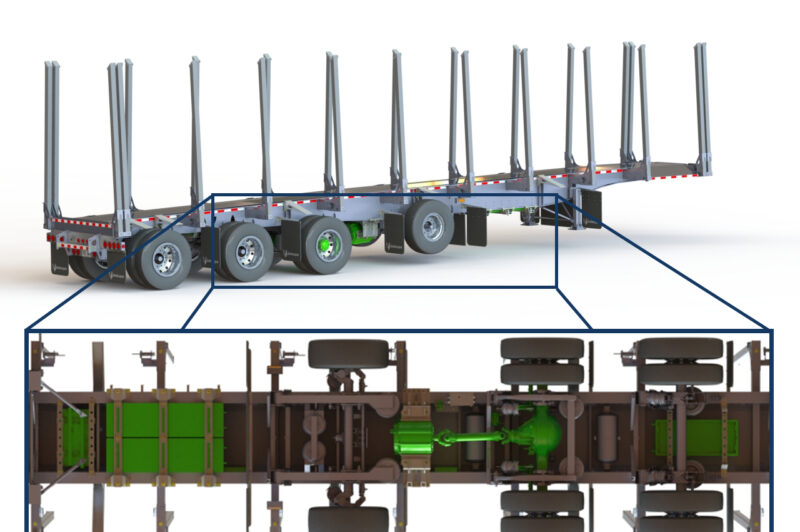

FPInnovations is currently developing a hybrid trailer for forestry operations, with plans to replace a conventional trailer axle with an electrically powered drive axle.

The project, worth approximately $2.5 million, is being carried out under Natural Resources Canada’s Clean Growth Program (CGP).

Among the promised benefits of the hybrid system, FPInnovations claims: fuel savings of up to 15% depending on the application and drive cycle; GHG emission reductions of up to 40 tonnes per truck per year, depending on duty cycle and utilization; and almost 50% better traction in slippery terrain.

The prototype will use regenerative braking to recharge the batteries, reduce brake fade, and increase safety in mountainous terrain, and it will be compatible with log and biomass trailers. There could also be significant benefits for the mining sector, the organization says.

Modifications will include the suspension for the electric axle itself, high-voltage components such as batteries and an inverter, and electric heating and cooling systems.

Dave Waknin, senior research scientist, transportation – advanced vehicle systems, says FPInnovations has been working since 2019 on this project, which has been delayed due to the pandemic.

“We have added other components and features to increase the safety of the system. We will monitor the load on the fifth wheel to prevent unwanted pushing forces from the trailer onto the truck. We will also monitor the wheel speed of the power axle to prevent wheel spin,” he adds.

Maximum peak power is 255 kW (342 hp), while maximum continuous power will be 190 kW (255 hp). Preliminary data collected in real-life forestry situations helped to better understand the driving cycles, power levels, and frequencies at which the engine brake is used.

Mack Sainte-Foy has provided two trucks for the project. One will pull a standard Deloupe Viking trailer, which will be used as a reference point when analyzing the test results. The other will pull a prototype Viking trailer that has been modified to include the electric propulsion system.

Subsequent testing will take place in three phases: functionality and safety testing in a controlled environment on the PMG Technologies track; controlled fuel economy tests in the forest; and then real-world operations testing in collaboration with the Boisaco lumber mill and the Star Express forestry transportation company.

FPInnovations says it overengineered the system to provide the needed durability. “Therefore, the current weight should not be considered representative. That being said, the trailer is equipped with Deloupe’s composite stakes to reduce weight,” says Waknin. “Once the testing is complete and the data is analyzed, we will be able to review the configuration and component selection to optimize the weight. That said, the final weight will depend on the application and requirements. Generally speaking, we should expect an additional weight of about 1.5 tons.”

Suppliers collaborating on the project include Dana TM4, Deloupe, Grayson Thermal Systems, Hendrickson, LTS Marine, Mack Sainte-Foy, Meritor, Michelin, Promark Electronics and Tycrop Trailers.

Leave a Reply