Geofencing – the virtual boundaries established by global positioning systems – has been around since the 1990s, and a growing number of Canadian fleets are turning to it to solve fleet management issues as diverse as security and productivity.

Quebec-headquartered C.A.T. began exploring the technology about half a year ago, and fleet vice-president – safety and driver development Michael Robinson says it’s on the right track.

Several reasons were behind the decision at the fleet that deploys technologies from Isaac Instruments, he says. Preventing truck and trailer thefts is one of them.

“Being able to track the equipment leaving the yard when you do not expect it to is very important,” Robinson explains. “Even though every truck nowadays has a GPS system, it is not a constant live tracking of every single vehicle. So, when the system sends you a message, saying the truck has left its location, [it’s] key to the security and safety of the loads.”

The bigger the fleet, the harder it is to track every truck and trailer on the move. Knowing the last time a trailer left a particular yard, and whose truck it was attached to, facilitates the search, he says. Knowing when a truck has arrived at a facility, and how long it has been waiting there, also helps communicate with customers.

How geofencing works

Trucks and trailers that come and go can be tracked using a variety of technologies, from global positioning systems (GPS); to wifi, Bluetooth and cellular signals; and RFID (radio frequency identification) tags and readers. The precise location-based information is then conveyed using messages and notifications through third-party apps.

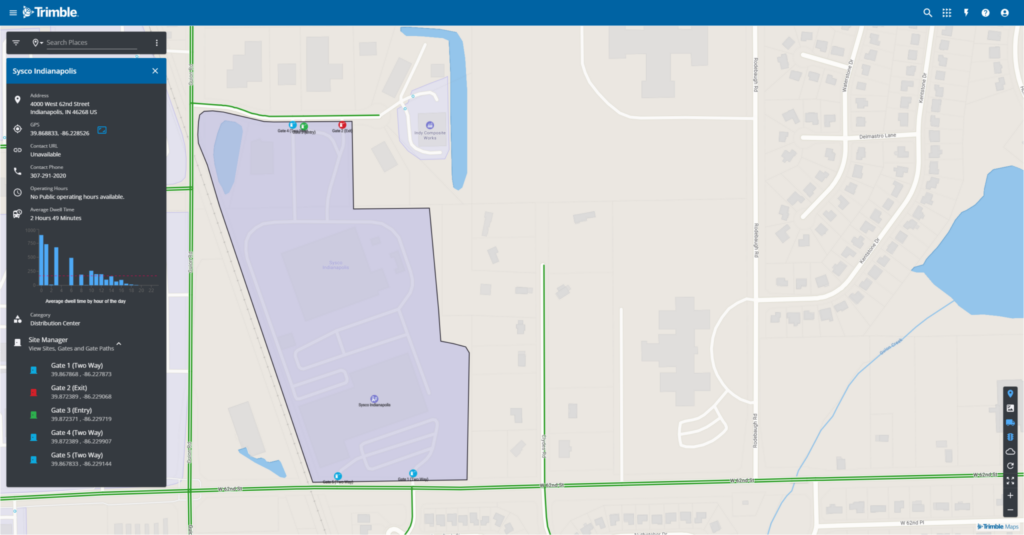

Trimble uses its own commercial location database to identify specific facilities that these equipment locations can be plotted against, and refines the details using high-resolution satellite images and machine learning. But teams in the U.S. and Canada also validate the details in person to ensure a finalized geofence accurately reflects what exists, says Rishi Mehra, Trimble’s vice president of product vision and experience.

The virtual “fence” can be far more detailed than a circle drawn on a map, too. Polygonal geofencing, such as the process used by C.A.T., involves establishing precise borders, exits and entrances.

Mehra says the switch from radial to polygonal geofencing represents one of the industry’s biggest trends.

From circles to polygons

“Now, people are realizing that we have to start using precise polygons because they have an impact on their operations, their ETA, and all the other downstream activities for workflow perspective,” he says.

A simple radius covers the roads leading to a facility, but can’t differentiate whether a driver is in a yard or just approaching it, he explains. Precise geofences on entrances and exits provide more accurate real-life data.

Trimble systems alone have established 2.5 million polygonal geofences, covering 4.8 million unique locations across Canada and the U.S. A Walmart and Home Depot might be identified as unique locations, for example, but fall within the geofence established for a mall.

“The mall entrance can be a single polygon geofence. [We] would get the entry and exit out of that. And the individual dwell times are computed by the locations for the Walmart and the Home Depot separately,” Mehra says, referring to the benefits.

Leave a Reply